03 DW

Dewatering

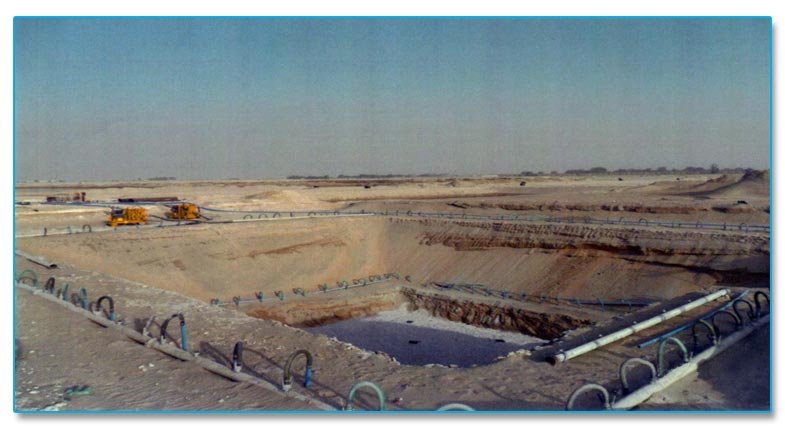

Dewatering is defined as the removal of the natural groundwater to a level below the normal water table to enable construction to be carried out in the dry or is the removal of water from solid material or soil by wet classification, centrifugation, filtration, or similar solid-liquid separation processes, such as removal of residual liquid from a filter cake by a filter press as part of various industrial processes. Construction dewatering, un watering, or water control are common terms used to describe removal or draining groundwater or surface water from a riverbed, construction site, caisson, or mine shaft, by pumping or evaporation. On a construction site, this dewatering may be implemented before subsurface excavation for foundations, shoring, or cellar space to lower the water table. This frequently involves the use of submersible "dewatering" pumps, centrifugal ("trash") pumps, eductors, or application of vacuum to well points.

Hudig

SCCL specializes in the supply of vacuum well point dewatering equipment and related turn-key services. Our vacuum assisted well point pumps and dewatering systems are available on an equipment rental and sale basis, and are recognized for their reliability and energy/environmental efficiencies. SCCCL primarily utilizes the Hudig line of vacuum well point pumps to address a broad diversity of applications. This includes high to low volume, high head discharge capabilities, high vacuum applications and extreme environmentally sensitive applications for use in construction dewatering, dual phase extraction and creek/river bypass applications. These pumps are recognized worldwide for their superior quality as well as their operational capabilities, which is in line with the standards that SCCCL expects in delivering exceptional service to its clients and the wider industry.

Deep well system

The deep well system is also a versatile pre drainage dewatering system which can pump high and low volumes of groundwater. This method is best suited to homogeneous aquifers that extend well below the bottom of the excavation. Deep well systems consist of one or more individual wells, each of which has its own submersible pump at the bottom of the well. Deep well systems are suitable for water-table or confined aquifers and will lower the water table 100 feet or more in a single lift without staging. SCCCL offers effective and innovative turn-key solutions to groundwater control problems using Deep Wells. We offer a full professional service from initial design, drilling, supply and installation of pumping equipment together with all associated appurtenances. Advantages 1. Ability to penetrate strata impervious to the jetting method of wellpoint systems. 2. Installation of up to 100 feet deep or more in a single stage. 3. Capable of pumping tens to thousands of gallons per minute per well. 4. Deep Wells can be effective when placed outside of the jobsite work area. Deep well dewatering systems are used when large volumes of groundwater must be pumped, highly permeable soils result in rapid recharging of the aquifer, and/or the depth of excavation excludes other dewatering methods.

Well point installation procedure

Well point dewatering involves the installation of riser pipes with a filter section on the lower 1.0m portion, connected to a common header pipe from which the water can be pumped by self priming centrifugal pump into the discharge system. uPVC riser pipes shall be driven into the ground through the use of water pressure. The jetting pump is connected to a Lance through which high pressure water is injected into the ground, forming a borehole into which the wellpoint can be installed. The Lance is rotated to create a gap around the wellpoint. Well points are to be installed every 1.0m Once the well point has been installed, the lance is held in position until the water being ejected out through the top of the boreholes runs clean. uPVC riser pipes shall be inserted into Pre-Drilled Bore Holes. The bore holes are made using a hydraulic 150mm core drill machine, anchored, and powered from a suitable excavator with an 8.0m reach and Hydraulic Accessory take off points on the main dipper arm. Once the borehole has been drilled to the desired depth, the well points can be inserted. Well points are to be inserted every 1.0m Upon completion of the installation of pre-determined number of well points, the well points shall be connected to the header pipe network by means of flexbows which in turn, is connected to the dewatering pump. The collected water produced by the ground water control system shall be discharged into a discharge header main which feeds the water to the settlement tank arrangement prior to discharging to waste < pond – sea – storm water

submersible pump

A submersible pump (or electric submersible pump (ESP)) is a device which has a hermetically sealed motor close-coupled to the pump body. The whole assembly is submerged in the fluid to be pumped. The main advantage of this type of pump is that it prevents pump cavitation, a problem associated with a high elevation difference between pump and the fluid surface. Submersible pumps push fluid to the surface as opposed to jet pumps having to pull fluids. Submersibles are more efficient than jet pumps.